[ad_1]

In relation to the operation of heavy vehicles, security is at all times a prime precedence. Among the many most important security elements in any industrial car are the brakes. And not using a absolutely useful brake system, a truck turns into a big threat to the motive force, different street customers, and the cargo it’s transporting. Common brake system inspections and upkeep are important for making certain that heavy truck brakes stay in optimum working situation, contributing to the general security of the car and stopping pricey repairs down the road. On this weblog, we’ll discover why brake upkeep is so vital for heavy vehicles, how usually brake inspections must be carried out, and the indicators of brake issues that truck drivers and fleet managers ought to look ahead to.

Why Heavy Truck Brake Upkeep is Essential

The significance of heavy truck brake inspections can’t be overstated. Heavy vehicles are continually on the street, typically masking 1000’s of miles every week. The sheer weight of those autos, mixed with the added stress of frequent stops, high-speed driving, and excessive climate situations, places important strain on the brake system. Over time, this stress may cause put on and tear on key elements equivalent to brake pads, rotors, drums, and hydraulic methods, all of that are very important for the truck’s braking efficiency.

With out common truck brake upkeep, these elements can deteriorate to the purpose the place the car’s braking capability turns into compromised. In worst-case eventualities, this will result in brake failure, inflicting accidents or extreme harm to the truck. For fleet operators, an out-of-service truck as a result of brake points can lead to important downtime and misplaced income. Moreover, severe accidents attributable to defective brakes can result in pricey legal responsibility claims, lawsuits, and insurance coverage hikes. Due to this fact, sustaining the brake system is not only a security problem—it’s additionally a monetary and operational concern for any enterprise that depends on industrial vehicles.

The Position of Common Brake Inspections

One of the efficient methods to keep up the braking system on heavy vehicles is thru common brake inspections. Brake inspection vehicles must be scheduled periodically to make sure that every truck’s brake elements are functioning as anticipated. Sometimes, industrial vehicles ought to endure brake inspections each 10,000 to fifteen,000 miles or after prolonged durations of heavy utilization. Nevertheless, this will fluctuate relying on the particular use case of the truck, equivalent to whether or not it operates primarily in city areas or on highways. City driving, with frequent stops and begins, locations extra pressure on the brakes and will require extra frequent inspections.

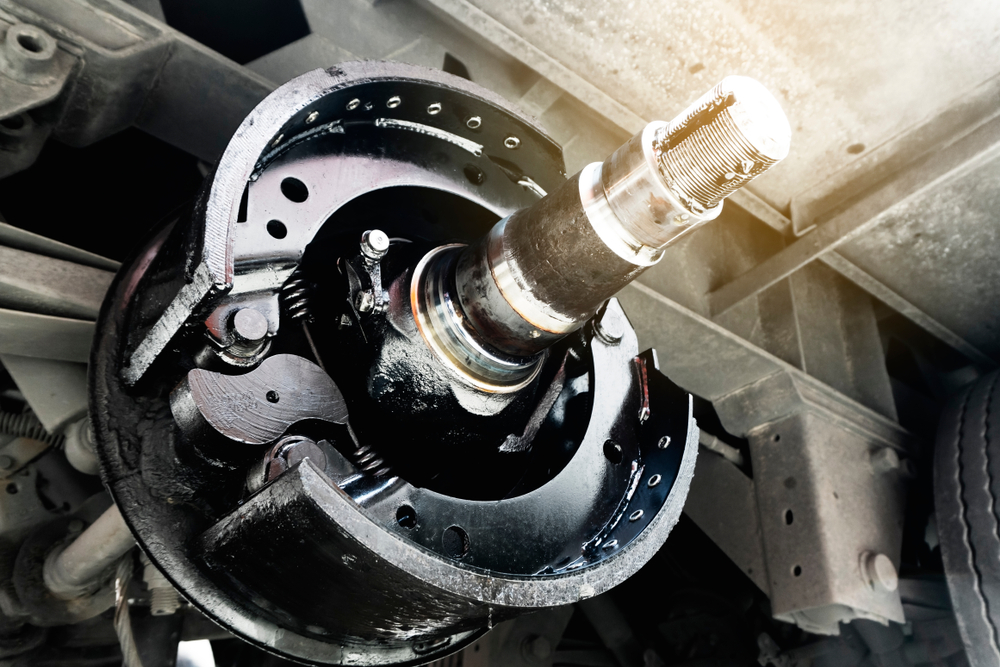

Throughout an inspection, a technician will verify numerous elements of the braking system, together with the brake pads, rotors, hydraulic fluids, brake strains, and different associated methods. They may also assess the efficiency of the air brake system, which is usually utilized in heavy vehicles. Air brakes are vital for offering the required stopping energy, and their efficiency must be often examined to make sure correct performance.

Failing to carry out common brake inspections can permit small points to go unnoticed, resulting in extra important issues down the street. For instance, a minor leak in a brake line or a slight imbalance within the air brake system won’t be instantly obvious to the motive force. Nevertheless, over time, these points can worsen, finally resulting in brake failure. Stopping such occurrences via common inspections is vital to sustaining security and operational effectivity.

The Risks of Neglecting Brake Upkeep

Neglecting brake upkeep can have severe penalties for truck drivers and their employers. The obvious threat is the elevated chance of accidents attributable to brake failure. Heavy vehicles require a big quantity of stopping energy, and with out correctly maintained brakes, stopping distances can improve dramatically, particularly when carrying a full load. This delay may be the distinction between avoiding a collision and inflicting a catastrophic accident.

One other hazard of uncared for brake upkeep is the potential for pricey repairs. Over time, worn-out brake pads and rotors can result in deeper harm inside the brake system. For instance, if brake pads are allowed to put on down utterly, the metallic backing plate can grind into the rotor, inflicting grooves and scoring which will require pricey rotor substitute. Equally, if air brake methods should not often serviced, points equivalent to contaminated air or leaks can compromise their effectiveness, resulting in costlier repairs and replacements.

For fleet managers, the prices related to uncared for brake upkeep lengthen past restore payments. A truck that’s out of service as a result of brake failure can disrupt schedules, resulting in delayed deliveries, lack of income, and pissed off prospects. In the long term, this will erode the status of the trucking firm, inflicting purchasers to hunt out rivals who supply extra dependable companies. Due to this fact, investing in common brake upkeep for industrial vehicles will not be solely a security measure however a approach to safeguard the corporate’s profitability and status.

Figuring out Indicators of Heavy Truck Brake Issues

Having the ability to determine the early indicators of heavy truck brake issues might help forestall catastrophic failure. It’s important for each drivers and fleet managers to concentrate on frequent indicators that point out the brakes might not be functioning optimally. One of the apparent indicators of brake bother is a noise, equivalent to squealing, grinding, or thumping sounds, when the brakes are utilized. This usually signifies that the brake pads are worn out or that particles has turn out to be lodged within the brake elements.

One other purple flag is that if the truck pulls to at least one aspect when braking. This might point out that the brake pads are erratically worn, or there could also be a problem with the brake fluid or the air brake system. Drivers must also be looking out for any vibrations within the brake pedal when strain is utilized. This may be attributable to warped rotors, which happen when the braking system is subjected to extreme warmth, usually as a result of extended or aggressive braking.

Moreover, if the truck’s stopping distance appears longer than common or the brakes really feel much less responsive, this can be an indication of brake fluid leaks or air strain points. Leaking brake fluid may cause the system to lose hydraulic strain, lowering braking energy. If the brake warning mild seems on the dashboard, it’s essential to examine the system instantly to find out whether or not the problem lies with the fluid degree, strain, or different elements.

Lastly, if there’s a noticeable lower in braking energy when descending steep grades or driving in difficult situations, it might point out a problem with the brake system’s capability to dissipate warmth. This could possibly be an indication of overheated brakes, worn-out brake linings, or points with the air brake system.

The Backside Line: Security and Effectivity Go Hand-in-Hand

The security of truck drivers and most people will depend on the reliability and performance of the brake system in heavy vehicles. Common brake upkeep and inspections are very important in stopping accidents, making certain car uptime, and avoiding pricey repairs. For fleet operators, it’s important to ascertain a proactive upkeep schedule that features common brake inspections to make sure that the truck brake system is at all times in optimum working situation. This not solely enhances truck security but additionally contributes to the graceful operation and monetary success of the enterprise.

Recognizing the indicators of brake issues and addressing them promptly is vital to stopping extra extreme points down the street. Whether or not you’re a truck driver or a fleet supervisor, sustaining a pointy concentrate on brake efficiency and security ought to at all times be a precedence. In spite of everything, the security of the motive force, cargo, and everybody else on the street will depend on the reliability of a heavy truck’s brake system.

[ad_2]

Source_link